These duties

are executed by adjusting the position of the closure member in the valve. This

may be done either manually or automatically. Manual valves serve three major

functions in fluid-handling systems: stopping and starting flow, monitoring

flow rate, and diverting the flow.

There is the classification of valves as their common function:

|

Isolation

Valves |

Regulatory

Valves |

Safety

Relief Valves |

Non-Returnable

Valves |

Special

Purpose Valves |

|

Ball

Valve |

Ball Valve |

Pressure relief valve |

Swing check |

Float valve |

|

Butterfly

Valve |

Butterfly Valve |

Vacuum relief valves |

Lift check valves |

Foot valve |

|

Diaphragm

Valve |

Diaphragm Valve |

|

|

Knife gate valve |

|

Gate

Valve |

Globe Valve |

|

|

Line blind valves |

|

Pinch

Valve |

Needle Valve |

|

|

|

|

Plug

valves |

|

|

|

|

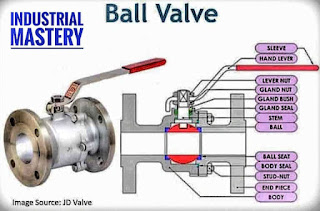

Ball valve:-

Advantages of Ball Valve

¨ Open and close quickly and provides leak-proof operation

¨ Maintains and regulate high temperature, high flow, and high pressure

¨ Low maintenance cost

¨ Low initial cost

¨ Long service life

Disadvantages of Ball Valve

¨ Very difficult to clean and prone to contamination

¨ Can’t use for permanent throttling

Butterfly valve:-

A butterfly

valve, in its simplest sense, opens, closes, or controls the flow. It is a

mechanical device used to regulate and isolate the flow of certain substances.

It acts as a passageway for the way in or exit of either air, water, or any other fluid. Their design features a disk mounted on a rod. When closed, this

disk blocks the passageway in which it is mounted, which happens when the

valve is turned by a quarter. When it is rotated by another quarter turn,

unrestricted flow or passage then occurs. Opening or closing the valve is

achieved by some turns; hence they are derived from a family of quarter-turn valves. This simple design is what makes

this valve a popular one.

The simplicity of this valve is

responsible for its very extensive and continuous use.

Advantages of Butterfly valves

¨ A simple and affordable design that comprises lesser parts which make it maintenance-friendly.

¨ Lightweight body makes it budget-friendly

¨ It can transfer mud, with a negligible fluid deposit in the pipeline outlet.

¨ Good sealing at low pressure and open and shut easily.

¨ Butterfly valve needs much less structural assistance than a ball valve of the same diameter needs.

Disadvantages of Butterfly valves

¨ A certain part of the disc always faces the flow, even when completely opened. The operation of a butterfly valve thus always leads to a pressure switch over the valve irrespective of the setting.

¨ It has a poor sealing function.

¨ Throttling by employing butterfly valves is restricted to low-pressure drop systems.

¨ Possible cavitation and choked flow is a worry when butterfly valves perform.

Globe valve:-

The

Globe valve is another very important and useful type of valve. It is known as a globe valve because of its spherical shape. The globe contains a seat and plug arrangement.

It is used to start, stop, and also regulate the flow of fluid. Because of its

perpendicular flow path of fluid, it is providing very good at throttling also. It provides

fewer leakage problems than the Gate valve. The globe valve gives a very high-pressure drop because of the

perpendicular flow path.

Advantages of Globe Valves

¨ Have throttling feature

¨ Opening and closing is fast compared to the gate valve

¨ It is fast-acting

Disadvantages of Globe Valves

¨ Not good for clean or sterile applications

¨ Very high-pressure drop

¨ Noisy in high-pressure applications

Gate valve:-

Gate

valve is the simplest type of valve also known as the On/Off valve Knife valve or slide valve. Gate valve is designed to operate either in fully open or

fully closed conditions. When the valve is fully open or the gate is in open condition

there is very negligible resistance to the flow of fluid and when it is in

closed condition or the gate is closed it will restrict the flow of fluid. They

are used in both above-ground and underground applications. The gate

valve can only work on either fully open or closed conditions hence it is very bad

at flow control. Now, let’s talk about different parts of the Gate valve.

Advantages of Gate valves

¨ Offers less resistance to fluid

¨ It can be used with slurries and viscous liquids

¨ Easy to maintain

Disadvantages of Gate valves

¨ Opening and closing is time-consuming

¨ Very bad at throttling

Plug valve:-

A plug valve can be defined as basically a quarter-turn rotary motion valve that

employs a narrowed or cylindrical plug to obstruct or open the flow. The disk

has a plug outline, which has an opening to pass the flow.

In the unfastened arrangement,

this bored passage is in line with the flow. When the plug is rotated 90

degrees from the unfastened arrangement, the solid part of the plug hinders the

flow. The plug valve is used in place of a gate valve where fast operation

is needed. This valve can also be used in high-pressure temperature services.

Advantages of Plug Valves

¨ The design of a plug valve is uncomplicated and clear with just a few parts

¨ This valve opens and closes fast.

¨ The inline maintenance of plug valves is feasible.

¨ This valve offers minimal resistance to the flow

¨ It provides a dependable leak-tight service

¨ The multiple port design helps to reduce the number of valves needed and allows a change in a flow direction

Disadvantages of Plug Valves

¨ The plug valves need a higher amount of force to operate. This happens due to high friction

¨ The bigger plug valves cannot be operated manually and requires an actuator to operate them.

¨ A pressure drop is encountered due to reducing port

¨ The plug valves are more expensive than ball valves for any given size and class

|

Type of valves |

Application |

Services |

|

Ball Valve |

1. Stopping

and starting flow 2. Moderate

throttling 3. Flow

diversion |

Gases Liquids Non-abrasive

slurries Vacuum Cryogenic |

|

Butterfly Valve |

1. Stopping and starting flow 2. Controlling flow the |

Gases Liquids Slurries Powder Granules Sanitary handling of pharmaceuticals

and foodstuffs Vacuum |

|

Globe valve |

1. Controlling the flow 2. Stopping

and starting flow 3. Frequent

valve operation |

Gases

essentially free of solids Liquids essentially

free of solids Vacuum Cryogenic |

|

Gate valve |

1. Stopping and starting flow 2. Infrequent operation |

Gases Liquids fluids carrying solids in suspension |

|

Plug valve |

1. Stopping

and starting flow 2. Moderate

throttling 3. Flow diversion |

Liquids Non-abrasive

slurries Abrasive

slurries for lubricated plug valves Sticky

fluids for eccentric and lift plug valves Sanitary

handling of pharmaceuticals and foodstuffs Vacuum |

0 Comments